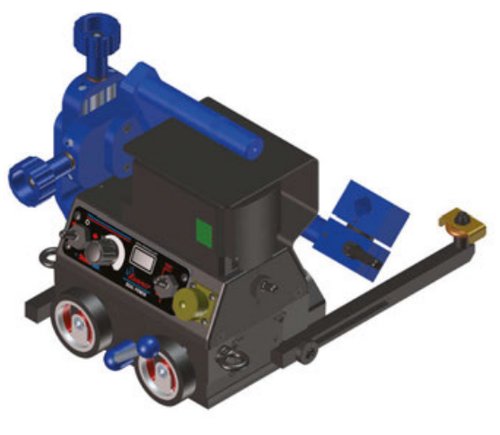

Li'l Runner Portable Fillet Welding Carriage

(Standard Version - Up to 40 IPM)

Increase your production and reduce your welding costs with

the Li’l Runner Automatic Fillet Welding Carriage. By providing

constant, non-stop travel at a regulated speed, Li’l Runner

produces consistent high-quality welds in a fraction of the time

required by hand welding. The regulated travel speed creates

weld bead geometry which is exact to your specifications,

reducing costly over welding and decreasing filler metal usage

by as much as 60%. Li’l Runner will produce quality welds

faster and with less cost than hand welding. At just over 17 lbs

(8 Kg), this compact, portable tractor can be carried anywhere.

the Li’l Runner Automatic Fillet Welding Carriage. By providing

constant, non-stop travel at a regulated speed, Li’l Runner

produces consistent high-quality welds in a fraction of the time

required by hand welding. The regulated travel speed creates

weld bead geometry which is exact to your specifications,

reducing costly over welding and decreasing filler metal usage

by as much as 60%. Li’l Runner will produce quality welds

faster and with less cost than hand welding. At just over 17 lbs

(8 Kg), this compact, portable tractor can be carried anywhere.

The Li’l Runner Welding Carriage is available in three unique versions:

(i) the standard version (up to 40 IPM); (ii) the high speed version (up to 86 IPM)

which can be used for cutting and welding applications; and

(iii) the dual power version (battery powered with a line power adapter).

The Li’l Runner family of carriages offer a broad range of capabilities in one

of the smallest fillet welders on the market today.

(i) the standard version (up to 40 IPM); (ii) the high speed version (up to 86 IPM)

which can be used for cutting and welding applications; and

(iii) the dual power version (battery powered with a line power adapter).

The Li’l Runner family of carriages offer a broad range of capabilities in one

of the smallest fillet welders on the market today.

FEATURES

- Compact, lightweight design with durable cast aluminum housing

- Positive magnetic traction permits out of position use

- Magnetic adhesion on/off lever permits easy set up and adjustment on work piece

- Maintenance-free, 4-wheel planetary gear drive system

- Digital LED display for presetting of travel speed

- Rapid clamp torch holder mechanism for different types of MIG/MAG torches

- Precise cross-slide torch adjustment

- Integrated automatic arc initiation

- Self-guiding roller arms eliminate the need for track

PRIMARY BENEFITS

- Increased arc time – no starts and stops

- Reduce wasted filler metal – eliminates over welding

- Consistent heat input reduces distortion

- Precise travel speed and torch angle reduces weld defects and costly rework

- Improves work environment – reduces fatigue and repetitive stress – removes operator from heat and fumes